"Smart" digital technologies of a modern dental laboratory eliminate errors and inaccuracies during the manufacture of aesthetic veneers and crowns.

The smile you dream of is closer than you think.

Smile of the 22nd century

As important as the presence of the human factor in any field, including dentistry, the fact remains that the future of medicine and dentistry lies on digital technologies.

Laboratory of MaryClinic, saturated with 3D technologies, undoubtedly surpasses traditional dental laboratories in terms of accuracy, speed and comfort.

A digital laboratory is an integral part of a modern dental clinic.

Dental laboratory MaryClinic

The digital laboratory of MaryClinic is equipped with the most advanced digital equipment, which allows producing high-quality and aesthetic crowns in a short time.

- MEDIT i700 intraoral scanner

- MEDIT i310 laboratory scanner

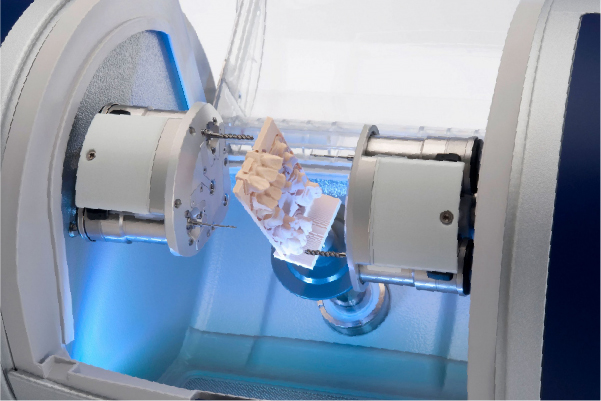

- CAD/CAM by japanese company ROLAND

- Ceramic oven by german company Ivoclar for firing

- Tabeo german oven for zirconia synthesis (firing)

- Phrozen Sonic Mini 8k 3D printer

-

The Digital Laboratory of Mary Clinic is a state-of-the-art, high-tech facility where individualized prosthetics, veneers, and orthodontic appliances are created using digital modeling and 3D printing with maximum precision and speed.

-

3D crowns are made using digital laboratory equipment, which is modeled by computer programs. At any time, you can visit our laboratory and follow to the process of manufacturing and modeling your crowns offline.

Replacing manual measurements of dental arches with 3D scanning.

In the standard method of obtaining sizes, dentists use silicone measuring material, which is inserted into the mouth for few minutes to obtain the size of the dental arch. This is not very pleasant process and unbearable, especially for those people who have gag reflex. With 3D scanning of dental arches, you are relieved of physical and psychological discomfort during obtaining sizes. Sizes obtained by digital scanning are accurate, thanks to which your crowns are also made with high accuracy, eliminating the need to obtain sizes twice.

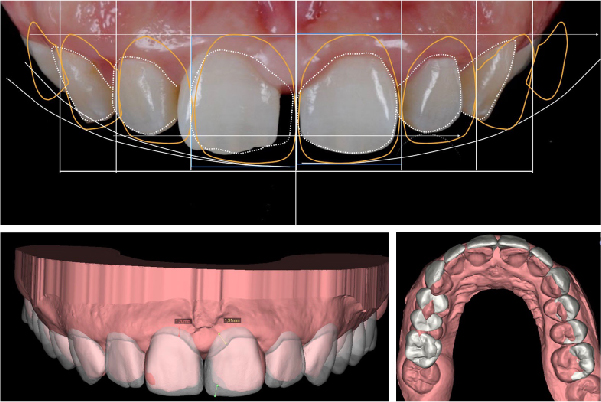

Virtual smile modeling

The obtained measurements are immediately sent to the laboratory, where your future smile is "programmed" with special programs. This allows you to get a high-precision digital model of your dental arch, which will be the basis for future zirconia crowns or ceramic veneers.

-

If the root of the tooth can be preserved, then we can obtain the size of your dental arch in the morning, and in the evening, the crown can be installed and you will not have aesthetic discomfort because of a broken tooth.

-

Fixed dental arch is possible to have with the insertion of 4-6 implants. Unlike classical implantation, when you have to wait 3-6 months, and then crowns can be installed, at MaryClinic you will have fixed dental arch immediately after implantation within 2-3 days. This is possible thanks to our experienced doctors and digital technologies working directly in the clinic.

Ceramic crown

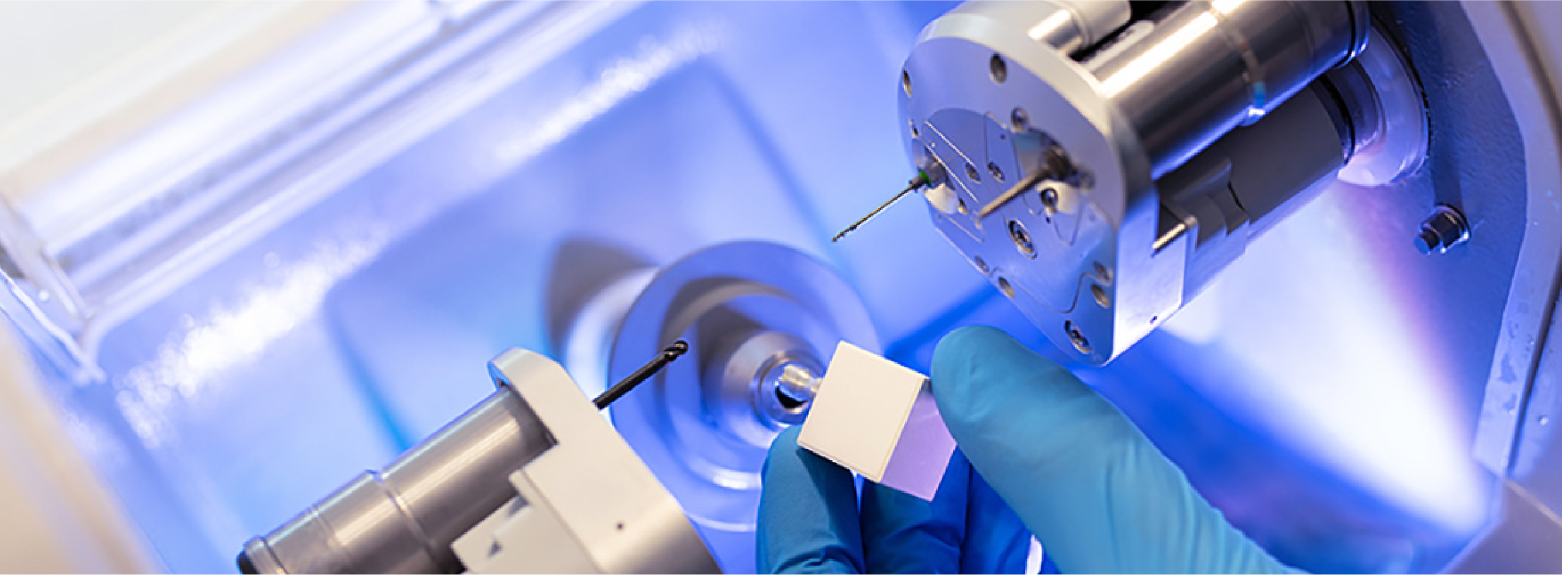

A dental technician models the anatomy of your crown with computer programs to the accuracy of micrometers and a milling machine manufactures it. The finished crown is sent to high-temperature ceramic oven, where it is fired at a temperature of about 1500°C, making the crown durable.

Man and digital technology

The human factor is involved at the last stage. A dental technician, like a "magician-artist" , chooses colors and gives shades to your crowns alike to natural colors of teeth. This is the stage that still requires the human factor to achieve super aesthetic result" .